Application:

Wire, PIPE, Sheet, Film, Profile, Plates, Pelletizing

Plastic Processed:

PE, PP, PVC, PA, EVA, PET, PC, FRPP/PVC, HDPE/PP, PE/PP, POE

Condition:

New

Screw Design:

Double-screw

Twin Screw Type:

Co-rotating Parallel Twin-screw

Screw Material:

40CrMoTi

Screw diameter (mm):

120

Screw L/D Ratio:

28:1

Screw Speed (rpm):

600 rpm

Showroom Location:

Canada, United Kingdom, United States, Italy, France, Germany, Viet Nam, Pakistan, Mexico, Russia, Thailand, Morocco, Kenya, South Korea, Chile, UAE, Colombia, Sri Lanka, Romania, Bangladesh, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan, Japan

Voltage:

380/415V

Dimension(L*W*H):

34000X11000X4500mm

Power (kW):

8000

Weight:

600000 KG

Warranty:

1 Year

Key Selling Points:

Automatic

Applicable Industries:

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining

Marketing Type:

New Product 2020

Video outgoing-inspection:

Provided

Machinery Test Report:

Provided

Warranty of core components:

1 Year

Core Components:

Bearing, Pump, Gear, Pressure vessel, Gearbox

Processing Type:

EVA, POE

Keywords:

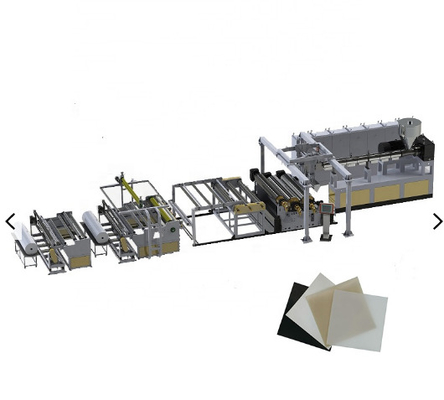

EVA POE film extrusion line

After Warranty Service:

Video technical support, Online support, Spare parts

メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!  メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!