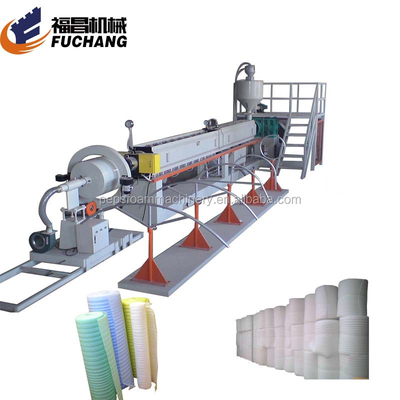

Application:

PIPE, Sheet, Film, Profile

Plastic Processed:

PE

Condition:

New

Screw Design:

Single-screw

Screw diameter (mm):

150 mm

Voltage:

380V/440V

Dimension(L*W*H):

24m*2.3m*.2.2m

Weight:

12 Ton

Warranty:

1 Year

Key Selling Points:

Easy to Operate

Applicable Industries:

Building Material Shops, Manufacturing Plant, Farms, Machinery Industry

After-sales Service Provided:

Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support, Engineers available to service machinery overseas

Output (kg/h):

100 - 200 kg/h

Automatic Grade:

Fully Automatic

Power:

45 KW

証明:

CE, ISO9001

Raw Material:

LDPE, GMS, Talc, Butane gas, etc.

Power Supply:

3Phase, 380V/440V, 50HZ/60HZ, can be changed

Extruder Capacity:

6-7t / 24hrs

Sheet Thickness:

1.0-10mm

Sheet Width:

1000-2000mm according to the sheet thickness

Foaming Ratio:

10-40

Installed Power:

110 KW

Other Materials:

Color Materbatch, Fire Retardant, etc.

Cooling Method:

Air-cooled, Water-cooled

メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!  メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!